A Clinician's Guide to Digital Denture Fabrication (Zahnprothese Online Anfertigen Lassen)

Digital denture fabrication—a process known in German-speaking regions as "zahnprothese online anfertigen lassen"—has evolved from a futuristic concept to a clinical reality. This digital workflow establishes a direct, streamlined link between a clinical practice and a remote dental laboratory, significantly reducing chair time and accelerating turnaround for both full and partial dentures. This guide provides an in-depth look at how to integrate this technology, blending clinical judgment with precision, efficiency, and patient-centric care.

The Digital Shift in Modern Prosthodontics

Removable prosthodontics is undergoing a significant transformation driven by robust digital workflows. For clinicians, dental students, and distributors, mastering this shift is essential for maintaining a competitive edge and delivering superior patient outcomes. The ability to commission a "zahnprothese online anfertigen lassen" is more than a convenience; it represents a fundamental change in patient care management, data acquisition, and lab communication.

This evolution is accelerating as key technologies—intraoral scanning, CAD/CAM systems, and high-resolution 3D printing—mature to offer predictable, accurate results. These advancements enable the instantaneous transfer of clinical data from the operatory to the laboratory, regardless of geographic distance. This digital pathway enhances precision, minimizes material waste, and fosters a more collaborative clinical-technical relationship.

Key Drivers of the Digital Prosthodontic Workflow

The transition toward online fabrication is propelled by several critical factors:

- Improved Accuracy: Intraoral scanners capture soft and hard tissue details with exceptional fidelity, mitigating the distortions often associated with traditional impression materials. This precision is foundational to achieving optimal fit and function.

- Enhanced Efficiency: The digital process is inherently faster. Instantaneous data transfer allows the laboratory to commence production almost immediately, reducing the number of patient appointments and shortening the overall treatment timeline.

- Better Patient Experience: Digital impressions eliminate the discomfort of traditional impression materials and cumbersome trays. Fewer appointments and quicker results contribute directly to higher patient satisfaction and case acceptance.

The demand for these solutions is substantial. A streamlined digital workflow can reduce the required appointments from the traditional five or more down to as few as two to four—a significant benefit for patients with mobility challenges.

Augmenting Clinical Expertise with Technology

It is crucial to view online fabrication as a powerful tool that augments, rather than replaces, clinical expertise. The clinician's diagnostic skills and treatment planning remain the cornerstone of successful outcomes. Digital tools simply provide a more efficient and precise means of executing that plan.

For example, when planning an implant-retained overdenture, the digital design phase allows for the virtual placement of attachments with pinpoint accuracy. This ensures optimal function and aesthetics are confirmed before any physical components are manufactured, aligning with modern implantology principles where meticulous planning dictates predictable success. To explore the components that facilitate these outcomes, review our article on Swiss dental solutions.

This shift empowers clinicians to focus more on patient-facing activities—diagnosis, treatment planning, and final adjustments—while leveraging the specialised capabilities of a remote digital lab for the technical fabrication. It optimises the use of valuable chair time.

By embracing this modern approach, practices can offer a higher standard of care and improve operational efficiency. The following sections provide a step-by-step clinical guide to effectively integrate the "zahnprothese online anfertigen lassen" process, ensuring exceptional and predictable results.

Acquiring High-Fidelity Digital Data: Scans and Secure Transfers

The integrity of the entire online denture fabrication process depends on the quality of the initial digital data. A suboptimal scan directly translates to a flawed prosthesis, leading to frustrating remakes and wasted chair time. Mastering the digital impression is not just a step—it is the foundational prerequisite for success.

This begins with proficiency in using an intraoral scanner. While modern scanners offer remarkable precision, their output is operator-dependent, especially when capturing a fully edentulous arch where anatomical landmarks are minimal.

Mastering the Edentulous Scan

Scanning edentulous ridges presents unique challenges compared to dentate arches. The mobile nature of soft tissue can disrupt the scanner's software, necessitating a systematic and repeatable technique.

- Define a Scan Path: Initiate the scan from a stable landmark, such as the incisive papilla or residual rugae, and methodically trace the ridge crest. A slow, deliberate "S" motion is effective for capturing buccal and lingual surfaces without losing tracking.

- Manage Mobile Tissues: The tongue and cheeks can compromise scan quality. Use a mirror or air syringe for retraction to ensure a clear, unobstructed view of the entire vestibular and flange area.

- Capture an Accurate Bite Registration: Establishing the correct vertical dimension of occlusion (VDO) is critical. If the patient's existing denture provides an accurate VDO, it can be used. Otherwise, custom bite blocks are required. Scan the bite registration with the patient in a stable, repeatable centric relation.

A crucial but often overlooked aspect of digital scans is capturing the "neutral zone"—the area where the forces from the tongue, lips, and cheeks are in equilibrium. Accurately recording this zone is a game-changer for the stability of a full denture and must be communicated to the laboratory.

Supplement geometric data with high-resolution clinical photographs. Photos are vital for communicating shade, characterization, and aesthetic goals to the technician. The photographic series should include full-face views (at rest and smiling), retracted views, and images of any existing prostheses for reference.

Secure File Transmission Protocols

Once captured, the data must be transmitted to the laboratory securely. The standard format is the STL (Standard Tessellation Language) file, a 3D map of the scanned anatomy. Given the potential size of these files, a reliable transmission method is required.

Adherence to data protection regulations like GDPR is a legal mandate. All patient data, including scans and photos, must be anonymized where possible and transmitted via an encrypted, secure portal. Standard email is never an appropriate channel for this sensitive information. A reputable laboratory will provide a secure platform for file uploads and communication, ensuring data safety and regulatory compliance.

Finally, utilizing validated digital libraries is key to achieving a precise fit for implant-retained prostheses. For clinicians using Alfa Gate systems, our comprehensive CAD/CAM dental technology libraries integrate seamlessly with design software. This guarantees that the virtual design perfectly matches the physical components, eliminating guesswork and ensuring a precise, passive fit for the final restoration.

By standardizing data capture and transmission protocols, you establish a repeatable, robust foundation for every case, leading to superior clinical outcomes and a more collaborative relationship with your laboratory partner.

Optimizing Clinician-Laboratory Collaboration

Once digital files are received by the laboratory, a dynamic collaboration between clinical judgment and technical artistry begins. Effective communication during this phase is what transforms a high-quality scan into an outstanding final prosthesis.

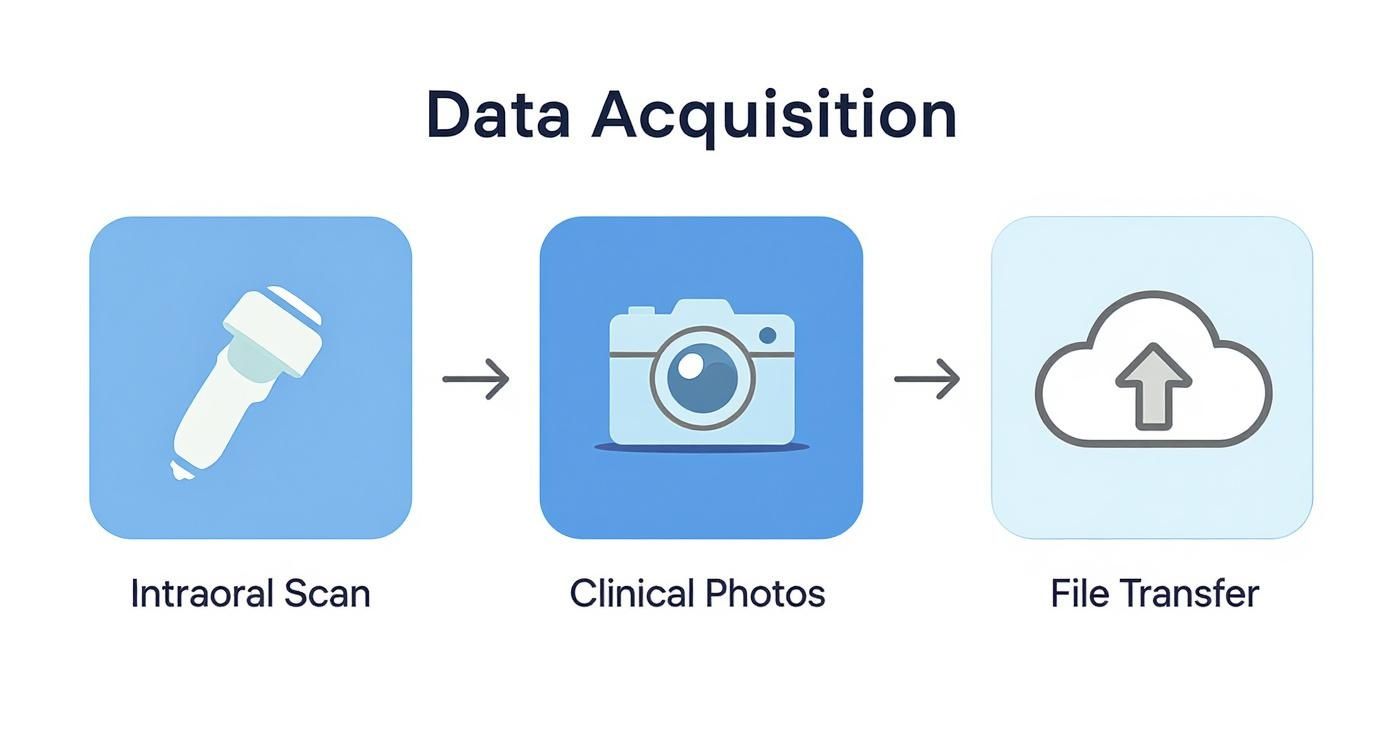

This visual guide outlines the essential data required by the laboratory, from the initial intraoral scan to the secure file transfer.

The combination of precise 3D data and detailed photographs provides the remote technician with the complete clinical context necessary for success.

Guiding the Virtual Design Process

The clinician's role is to direct the virtual design, not merely approve it. Translate chairside observations into clear, actionable digital instructions. Most laboratories use a secure online portal for reviewing the virtual wax-up, offering the first opportunity to evaluate tooth arrangement, vertical dimension, and the occlusal scheme before any material is committed.

Feedback must be specific. A comment like "The teeth look too big" is insufficient. Instead, provide precise instructions: "Reduce the mesiodistal width of teeth 12 and 22 by 0.5 mm" or "Increase the overjet by 1 mm to improve phonetics." Utilize the platform's annotation tools to mark the 3D model directly, eliminating ambiguity.

Selecting Appropriate Materials

The digital workflow provides access to an advanced portfolio of materials. The selection depends on the clinical application, whether it is a provisional restoration or a definitive, implant-retained solution.

- Milled PMMA (Polymethyl Methacrylate): An excellent choice for long-term provisionals or even final prostheses. Milled from a solid block, it is dense and non-porous, offering high resistance to staining and wear.

- 3D-Printed Resins: Ideal for diagnostic try-ins and immediate dentures. Modern biocompatible resins are strong and accurate, providing a cost-effective method to verify fit, function, and aesthetics before fabricating the final prosthesis.

- Milled Zirconia: For definitive, implant-supported prostheses requiring maximum strength and aesthetics, monolithic zirconia is the premier choice. It is particularly suitable for full-arch restorations, especially when combined with precision components like Alfa Gate Multi-Unit Abutments that ensure a passive, stress-free fit.

The laboratory should provide a material data sheet for any selected material. Reviewing this document is essential to confirm biocompatibility and verify that the mechanical properties are suitable for the clinical situation. A deep understanding of material science is critical to leveraging the full potential of digital prosthodontics, a topic explored further in our article on CAD/CAM dental technology.

The digital design review is not a passive approval step; it is an active clinical intervention. Your detailed feedback is the primary control mechanism ensuring the lab's technical execution aligns perfectly with your treatment plan.

Meticulous management of this virtual collaboration eliminates guesswork and dramatically reduces the need for extensive chairside adjustments at the final delivery.

Traditional vs. Digital Workflow Comparison

This table highlights the fundamental shift from a manual, iterative process to a precise, digitally driven one.

| Stage | Traditional Workflow | Digital Online Workflow ('Zahnprothese Online Anfertigen Lassen') |

|---|---|---|

| Impression | Physical impressions (alginate, PVS); prone to distortion. | Intraoral scan (STL file); highly accurate and immediate. |

| Model Creation | Plaster/stone models poured by hand. | 3D printed models or a completely model-less workflow. |

| Bite Registration | Wax rims and manual articulation. | Digital bite scan; occlusal scheme designed in software. |

| Try-In | Wax try-in; requires multiple patient visits for adjustments. | 3D printed resin try-in; validates fit and aesthetics in one go. |

| Communication | Phone calls, written scripts, potential for misinterpretation. | Direct annotations on 3D models, visual feedback loop. |

| Final Delivery | Manual processing and finishing; often needs significant chairside adjustment. | Milled or printed from final design; minimal to no adjustments needed. |

The digital workflow systematically removes variables that have historically led to inaccuracies and remakes. This tight communication loop, combined with material science expertise, ensures the final prosthesis meets exacting clinical standards and patient expectations.

For dental professionals looking to integrate these advanced workflows, Alfa Gate offers robust solutions. Explore partnership opportunities by inquiring to Become a distributor.

Translating Digital Design to Chairside Reality

Upon approval of the virtual design, the laboratory initiates fabrication, transforming the digital file into a physical prosthesis. This process relies on advanced manufacturing technologies to ensure the physical outcome precisely mirrors the on-screen design. A successful clinical trial fitting is the critical link to ensuring predictable results when you "zahnprothese online anfertigen lassen."

Modern laboratories primarily utilize two methods: multi-axis milling and high-resolution 3D printing. Milling is a subtractive process that carves the prosthesis from a solid block of material like PMMA or zirconia, resulting in a dense, strong final product. Conversely, 3D printing is an additive process that builds the object layer by layer from a liquid resin, ideal for rapidly producing detailed trial prostheses or surgical guides.

The Critical Importance of the Trial Fitting

The clinical trial fitting is an indispensable step in the online fabrication workflow. The 3D-printed try-in, typically made from a biocompatible resin, serves as the most important quality control check. It provides an opportunity to physically validate every aspect of the design—fit, function, and aesthetics—in the patient's mouth before committing to the final, more costly material. This single appointment can prevent expensive, time-consuming remakes.

The efficiency of this digital approach is significant. In the German dental market, digital workflows have been shown to reduce patient appointments by up to 50%, with some clinics delivering final dentures in as little as four to six weeks. For more on these trends, discover more insights about the dental prosthetics market on fortunebusinessinsights.com.

A Clinical Checklist for Evaluating the Try-In

A systematic evaluation of the printed prototype is essential for making final, critical adjustments.

- Assess Fit and Stability: Confirm a passive and stable fit on the ridge. Use a pressure-indicating paste to identify any high spots that could cause tissue irritation.

- Verify Occlusion and VDO: Check the vertical dimension and ensure balanced contacts in centric relation and during excursive movements.

- Evaluate Phonetics: Ask the patient to speak and listen for phonetic issues, such as lisping or slurring, particularly with sibilant ("S") sounds. This can indicate incorrect tooth position or palatal thickness.

- Confirm Aesthetics: Evaluate the smile line, tooth position, and lip support. This is the final opportunity to confirm with the patient that the aesthetic outcome meets their expectations.

For implant-retained cases, model accuracy is paramount. Using high-quality components like Alfa Gate's digital analogs for printed models is non-negotiable. They ensure the physical model is a perfect replica of the intraoral implant positions, guaranteeing a passive fit for the final prosthesis.

The trial fitting is your final opportunity to control the outcome. Every adjustment made to the printed try-in must be meticulously documented and communicated back to the lab. A new scan of the adjusted prototype is often the most reliable way to transfer this information.

Mastering the trial stage ensures the final delivery appointment is efficient, requiring minimal to no chairside adjustments. This reinforces the value of the digital workflow by delivering a predictable result that meets both clinical standards and patient expectations. If you are looking to expand your digital service offerings, contact us about becoming a distributor.

Integrating Online Fabrication into Clinical Practice

Adopting a digital prosthesis workflow is a strategic decision that requires a comprehensive plan for integration, encompassing final delivery, laboratory partnerships, and administrative protocols. Successfully implementing the "zahnprothese online anfertigen lassen" process can make it a profitable and efficient standard of care.

The final delivery appointment should be the culmination of meticulous digital planning—a brief and satisfying conclusion. The primary tasks should involve minor occlusal adjustments, verification of fit, and providing the patient with clear home care instructions. Minimal adjustments at this stage are a key indicator of a well-executed digital workflow.

Establishing Robust Clinical and Administrative Protocols

For this modern approach to become standard practice, internal systems must be optimized to support remote fabrication seamlessly.

Successful integration depends on several key elements:

- Selecting the Right Laboratory Partner: A suitable partner must possess not only technical skill but also excellent communication capabilities. They should have validated workflows for your preferred materials and utilize secure, GDPR-compliant platforms for data exchange.

- Defining Clear Communication Channels: Establish a clear protocol for case submission, design feedback, and query resolution. Standardized terminology and shared expectations from the outset prevent costly misunderstandings.

- Training the Entire Team: All staff members, from clinical assistants to administrative personnel, must understand the digital workflow. They should be equipped to explain the process to patients, manage digital files, and schedule appointments appropriately.

A scalable and predictable online fabrication process is built on a well-defined, repeatable workflow that every team member understands and can execute consistently.

Managing Patient Expectations and Administrative Tasks

It is essential to set realistic patient expectations from the initial consultation. Communicate the benefits, such as fewer appointments and the absence of traditional impressions, while also being transparent about the timeline and the importance of their feedback during the try-in stage.

Administratively, consent forms must be updated to include language specific to the collection and secure transmission of digital data to a third-party laboratory. Furthermore, ensure that billing codes accurately reflect the use of modern digital techniques to secure proper reimbursement.

The Broader Context of Prosthetic Care

Market data underscores the value of efficient prosthetic solutions. The prevalence of removable dental prostheses in regions like Germany creates consistent demand for high-quality, rapid fabrication. With an average prosthesis lifespan of about five years and 25% requiring replacement thereafter, the need for improved workflows is clear. An estimated 16 million people in Germany wear some form of removable prosthesis, highlighting the relevance of online services. For more detailed data, read the full research about dental prosthesis users on de.statista.com.

By refining these internal processes, you can confidently make online prosthesis fabrication a core service, delivering superior outcomes more efficiently. For implant-retained cases, integrating components like the Alfa Gate Ball Attachment System into your digital library ensures precision from the design phase onward.

Ready to explore how Alfa Gate’s digital solutions can enhance your practice or distribution network? Please contact us to learn more.

Frequently Asked Questions About Digital Denture Fabrication

Transitioning to a digital workflow for prosthodontics is a significant change that naturally raises questions. From clinical indications to managing adjustments, understanding the details is key to achieving optimal outcomes. Here are answers to common queries from clinicians exploring the "zahnprothese online anfertigen lassen" process.

What are the ideal clinical indications for a digital denture workflow?

The digital approach is highly effective for complete and partial edentulism, particularly in patients with well-formed, stable alveolar ridges. Such anatomy is ideal for intraoral scanners, enabling the capture of highly accurate data that forms the basis of the entire process. It is also an excellent option for patients who have difficulty attending multiple appointments or who desire an accelerated treatment timeline.

However, a traditional workflow may still be preferable for cases involving severe ridge resorption, complex maxillofacial defects, or challenging occlusal schemes that benefit from a hands-on diagnostic phase.

How do I ensure regulatory compliance when working with remote labs?

As the prescribing clinician, you bear the ultimate responsibility for regulatory compliance. Thoroughly vet any potential laboratory partner to ensure they are certified and exclusively use CE-marked materials compliant with the EU's Medical Device Regulation (MDR).

All patient data, including STL files and clinical photographs, must be transmitted via a secure, GDPR-compliant channel. Additionally, patient consent forms must be updated to explicitly state that digital data will be acquired and transmitted to a third-party laboratory for the fabrication of their prosthesis.

What is the most effective way to manage adjustments?

The key to an efficient digital denture process is to perform all major adjustments during the trial fitting, not at the final delivery. The 3D-printed try-in is an essential diagnostic tool for this purpose.

At the try-in appointment, use pressure-indicating paste to identify and relieve any high spots on the intaglio surface. Adjust the resin prototype directly in the chair. Document every modification with new scans or detailed photographs and communicate these changes with clear instructions back to the laboratory.

Pro Tip: If you nail the try-in stage, the final prosthesis should need very few, if any, chairside tweaks. If you find yourself making significant changes at the final fitting, it almost always points back to a problem with the initial scan or something missed during the trial.

Which Alfa Gate components are optimized for digital overdentures?

Alfa Gate’s systems are designed to fully support a digital workflow. We provide complete digital libraries for major CAD systems, streamlining the design process for implant-retained overdentures.

For these cases, our LOCATOR attachments are a preferred choice due to their self-aligning design, which simplifies seating for patients, and their customizable retention levels, which provide precise clinical control.

For fixed-removable solutions requiring maximum stability, our multi-unit abutments offer a robust and predictable platform for screw-retained prostheses, ensuring a passive fit and optimal load distribution. Success depends on the laboratory using the official Alfa Gate digital libraries during the design phase to guarantee absolute precision.

By integrating these protocols and utilizing components designed for digital workflows, you can confidently transition to a higher standard of prosthetic care. Alfa Gate is committed to providing the systems and support that clinicians and distributors need to excel in modern implant dentistry.

Ready to explore how our digital solutions can benefit your practice or distribution network? Contact Us today to speak with an expert and learn more about our advanced implant systems.