The Role of 3D Printers in Modern Dental Technology

3D printing, or 3d drucker zahntechnik, is not merely a new tool but a fundamental reimagining of the traditional dental workflow. This technology enables dental laboratories and clinics to transition from analogue methods to producing highly precise, patient-specific devices—from models and surgical guides to provisional restorations. It delivers a level of speed and consistency that was previously unattainable, solidifying its place as a cornerstone of modern dentistry.

The Digital Shift in Dental Technology

For decades, dental technology was a craft reliant on manual skill. Technicians used physical impressions and handcrafted models, a process inherently susceptible to human error and material inconsistencies. The transition to a digital workflow offers a more predictable and efficient path to achieving superior clinical results. This evolution is driven by clear operational advantages and a commitment to advancing patient care.

This paradigm shift empowers dental professionals to deliver a higher standard of care. The process begins with capturing precise anatomical data using intraoral or desktop scanners. This data is then used to design meticulous restorations in CAD software, creating a digital blueprint. Finally, a 3D printer materializes this blueprint, constructing a physical object layer by microscopic layer. To understand how this integrates with other digital tools, explore our article on CAD CAM Zahntechnik.

Key Drivers of Digital Adoption

The move towards 3D printing in dentistry is a direct response to clinical challenges. Several key factors are accelerating its adoption:

- Enhanced Precision: Digital workflows eliminate many variables inherent in analogue techniques, resulting in better-fitting prosthetics and more accurate surgical guides for predictable osseointegration.

- Increased Efficiency and Speed: Laboratories can print multiple unique components simultaneously, dramatically reducing turnaround times for crowns, bridges, and implant-supported appliances.

- Patient-Specific Customization: Every device is designed directly from a patient’s unique anatomical data, ensuring a customized fit and function that optimizes clinical outcomes.

- Improved Cost-Effectiveness: Automating production reduces manual labour costs, while additive manufacturing minimizes material waste, leading to significant long-term savings.

Market data validates this trend. In Germany, the dental 3D printing market generated USD 235.5 million in 2023 and continues on a steep growth trajectory, demonstrating the industry's commitment to these technologies. You can discover more insights about the German dental 3D printing market from Grand View Research.

By embracing a digital-first mindset, dental practices and labs are better equipped to deliver superior clinical outcomes. The focus shifts from labour-intensive fabrication to data-driven design and predictable production, ultimately benefiting both the clinician and the patient.

Ultimately, integrating a 3d drucker zahntechnik workflow allows professionals to overcome the limitations of traditional methods. It forges a seamless link between diagnostics, treatment planning, and final restoration, setting a new standard for quality and care in implantology and restorative dentistry.

Core Dental 3D Printing Technologies Explained

Entering the world of 3d drucker zahntechnik often involves navigating a landscape of acronyms: SLA, DLP, SLS, and SLM. While the technical jargon can be dense, the practical application of these technologies is what truly matters for a dental lab or clinic.

The primary objective is to match the right technology to the specific clinical task. Just as a clinician selects specific instruments for a procedure, choosing the appropriate 3D printing technology is the first step toward achieving predictable, high-quality patient outcomes.

Resin-Based Printing: The Workhorse of Dental Labs

The majority of dental 3D printing utilizes photopolymerization, where a liquid resin is cured by a light source to build an object layer by layer. The two dominant technologies in this category are Stereolithography (SLA) and Digital Light Processing (DLP).

Stereolithography (SLA) is the original 3D printing method. It employs a highly precise laser to trace the shape of each layer onto the resin. This meticulous process delivers an exceptionally smooth surface finish, making it ideal for applications requiring extreme accuracy, such as master models for crown and bridge or custom abutment analogues where micron-level detail is critical.

Digital Light Processing (DLP) uses a digital projector to expose an entire layer of resin at once. This method is significantly faster than SLA, particularly for full build plates, making it the preferred technology for producing daily essentials like orthodontic models, surgical guides, and splints efficiently.

While both SLA and DLP produce highly detailed parts, the choice between them involves a trade-off between absolute precision and production speed. DLP excels in high-volume laboratory settings, whereas SLA is invaluable for complex cases where the finest details are non-negotiable.

Powder-Based Printing: For High-Strength Applications

For components requiring superior mechanical strength and long-term biocompatibility, such as metal frameworks or definitive prosthetics, powder-based printing technologies like Selective Laser Sintering (SLS) and Selective Laser Melting (SLM) are essential.

These systems spread a thin layer of fine powder (polymer or metal) and use a powerful laser to fuse the particles together according to the digital design.

- Selective Laser Sintering (SLS) typically uses polymer powders like nylon. The laser sinters the particles, fusing them to create strong, durable, and lightweight parts suitable for functional prototypes or complex frameworks.

- Selective Laser Melting (SLM) is used for metals like titanium and cobalt-chrome. The laser fully melts the powder, creating dense, solid metal parts with material properties often superior to traditionally cast or milled components. This technology is ideal for high-end custom implant abutments and removable partial denture frameworks, designed to integrate seamlessly with systems like Alfa Gate's prosthetic components.

To clarify the applications, here is a practical comparison:

Comparing Key Dental 3D Printing Technologies

This table provides a side-by-side comparison of common 3D printing technologies in dentistry, highlighting their applications, advantages, and limitations to guide professional decision-making.

| Technology | Primary Dental Applications | Key Advantages | Considerations |

|---|---|---|---|

| SLA | High-precision models (crown & bridge), custom abutment analogues, castable patterns | Exceptional surface finish, very high accuracy, fine detail resolution | Slower print speeds, typically smaller build volume |

| DLP | Study models, surgical guides, splints, temporary restorations, orthodontic aligners | Very fast print speeds, ideal for high-volume production, good accuracy | Can show layer lines on angled surfaces, pixelation can affect fine detail |

| SLS | Durable functional prototypes, strong yet lightweight frameworks | No support structures needed, excellent mechanical properties | Rougher surface finish, higher initial equipment cost, limited material options |

| SLM | Custom implant abutments, RPD frameworks, metal copings, permanent crowns | Produces fully dense, strong metal parts, high biocompatibility | Very high equipment and material costs, requires extensive post-processing |

Selecting the right technology requires a clear understanding of your clinical objectives. Our guide on digital workflows in implantology can help contextualize these tools within a modern practice. A clinic specializing in orthodontics will benefit from a high-speed DLP printer, while a laboratory handling advanced implant cases may require the capabilities of an SLM machine.

Ultimately, the optimal 3d drucker zahntechnik is one that aligns with your production needs, material requirements, and budget. When applied correctly, these technologies can significantly enhance efficiency and patient outcomes.

Choosing the Right Materials for Clinical Success

A sophisticated 3d drucker zahntechnik is only as effective as the materials it utilizes. Material selection is a critical clinical decision impacting patient safety, treatment longevity, and final aesthetics. The chosen material dictates the final product's strength, biocompatibility, and functional performance within the oral environment.

Different clinical applications demand distinct material properties. A surgical guide requires exceptional rigidity to ensure precise implant placement, while a provisional crown must balance durability with a natural appearance. Let's examine the key material categories and their practical applications.

The Versatility of Photopolymer Resins

Photopolymer resins are the daily workhorse in most digital dental labs. These light-curable liquids are available in numerous formulations, each optimized for a specific task. They are popular for their ability to produce high-resolution parts with excellent accuracy and a smooth finish, making them suitable for a wide range of applications.

When selecting a resin, biocompatibility is the foremost priority. Materials intended for intraoral use must meet strict regulatory standards, such as Class I for devices with temporary contact (e.g., surgical guides) or Class IIa for those remaining in the mouth for longer periods (e.g., splints, temporary crowns).

Here is a breakdown of common resin types and their uses:

- Model Resins: Engineered to produce accurate, stable dental models with crisp details, ideal for diagnostics, crown and bridge models, or implant analogues.

- Surgical Guide Resins: A Class I biocompatible material formulated for extreme stiffness and fracture resistance, crucial for maintaining the accuracy of implant placement.

- Castable Resins: Designed to burn out cleanly without residue, serving as a digital alternative to traditional wax-ups for casting or pressing copings, frameworks, and full-contour crowns.

- Temporary Crown and Bridge Resins: As Class IIa biocompatible materials, these offer excellent mechanical strength and wear resistance. They are available in various tooth shades to create functional and aesthetic provisional restorations.

Advanced Polymers and Metals for Final Restorations

While resins cover most routine applications, the demand for strong, long-term solutions has driven advancements in material science. High-performance polymers and metals, printed with SLS or SLM technologies, are now used for definitive restorations and frameworks with strength comparable to traditional fabrications.

Biocompatible polymers like PEEK (Polyetheretherketone) are increasingly used for lightweight, metal-free frameworks. For ultimate strength, metals like titanium and cobalt-chrome remain the gold standard. They are used to print custom abutments, implant bars, and complex frameworks that integrate with sophisticated systems. The ability to select the ideal material for each component is a major advantage of digital workflows, and Alfa Gate’s comprehensive range of prosthetic solutions is designed for seamless compatibility with these modern materials.

A successful clinical outcome is built on a foundation of intelligent material choices. The ability to match a material’s specific properties—biocompatibility, flexural strength, aesthetics—to the clinical need is what elevates a 3D-printed component from a mere part to a successful clinical solution.

The market for these specialized materials is expanding. By 2025, Germany’s dental 3D printing materials industry is projected to reach USD 5.10 million, with a steady growth rate of 2.3% CAGR. This highlights the industry's shift towards advanced, application-specific materials that enhance efficiency and patient care. You can read the full research on material market trends from Polito.

Mastering material properties is fundamental to leveraging this technology. Our educational resources on digital workflows can help your team excel in this vital aspect of modern dental technology.

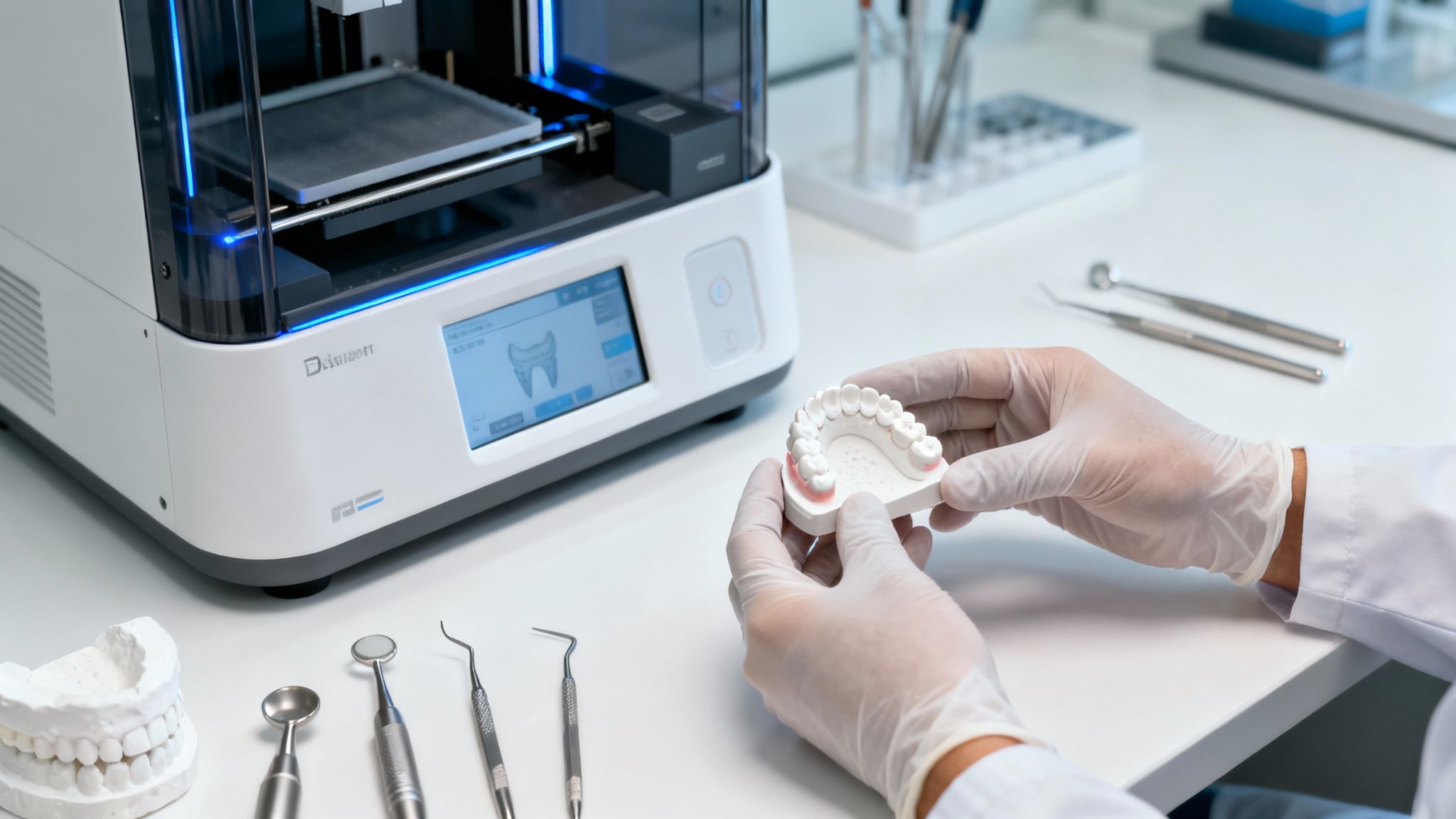

Mapping the Digital Implant Workflow: From Scan to Crown

The true value of a 3d drucker zahntechnik lies in its integration within a connected digital workflow that streamlines every step of implant treatment. This process replaces fragmented, traditional methods with a seamless digital path from initial patient scan to final crown placement. The result is a highly predictable, accurate, and efficient system that improves clinical outcomes and the patient experience.

This modern approach eliminates uncomfortable physical impressions, ensuring that every decision is based on precise data. This guarantees that the digital plan is accurately translated into the clinical outcome.

Step 1: Capturing Precise Data with Digital Scanning

The process begins with an intraoral scan. A clinician uses a handheld scanner to capture a detailed 3D digital model of the patient's dentition and soft tissues. This data is available instantly, avoiding the inaccuracies and distortions common with conventional impression materials.

For comprehensive planning, this data is combined with a Cone Beam Computed Tomography (CBCT) scan, which provides critical information about the underlying bone structure, nerve pathways, and sinus cavities. Merging the intraoral scan (STL file) with the CBCT scan (DICOM file) creates a complete virtual replica of the patient's anatomy. This "digital twin" is the foundation for precise treatment planning. You can explore this process further in our article on the fundamentals of digital volume tomography.

Step 2: Designing the Outcome with CAD Software

With a complete digital model, the process moves to the Computer-Aided Design (CAD) phase. In this virtual environment, the clinician or lab technician can:

- Virtually place the implant in the optimal position, considering bone density, angulation, and prosthetic requirements.

- Design a custom surgical guide to ensure sub-millimeter accuracy during implant placement.

- Create temporary and final restorations, such as custom abutments and crowns, to achieve a flawless fit and aesthetic result.

This stage is driven by data and collaboration, allowing the dental team to visualize the final outcome before treatment begins, thereby minimizing unforeseen complications.

The CAD phase is where clinical intent becomes a digital blueprint. It transforms diagnostic data into a precise, actionable plan, ensuring that every component—from the implant to the crown—is designed to function harmoniously within the patient's unique anatomy.

Step 3: Bringing the Design to Life with 3D Printing

Once the digital designs are finalized, the 3d drucker zahntechnik begins its work. The CAD files are sent to the printer, which builds the physical parts layer by layer. The availability of specialized materials allows for the production of everything from surgical tools to the prosthetics themselves.

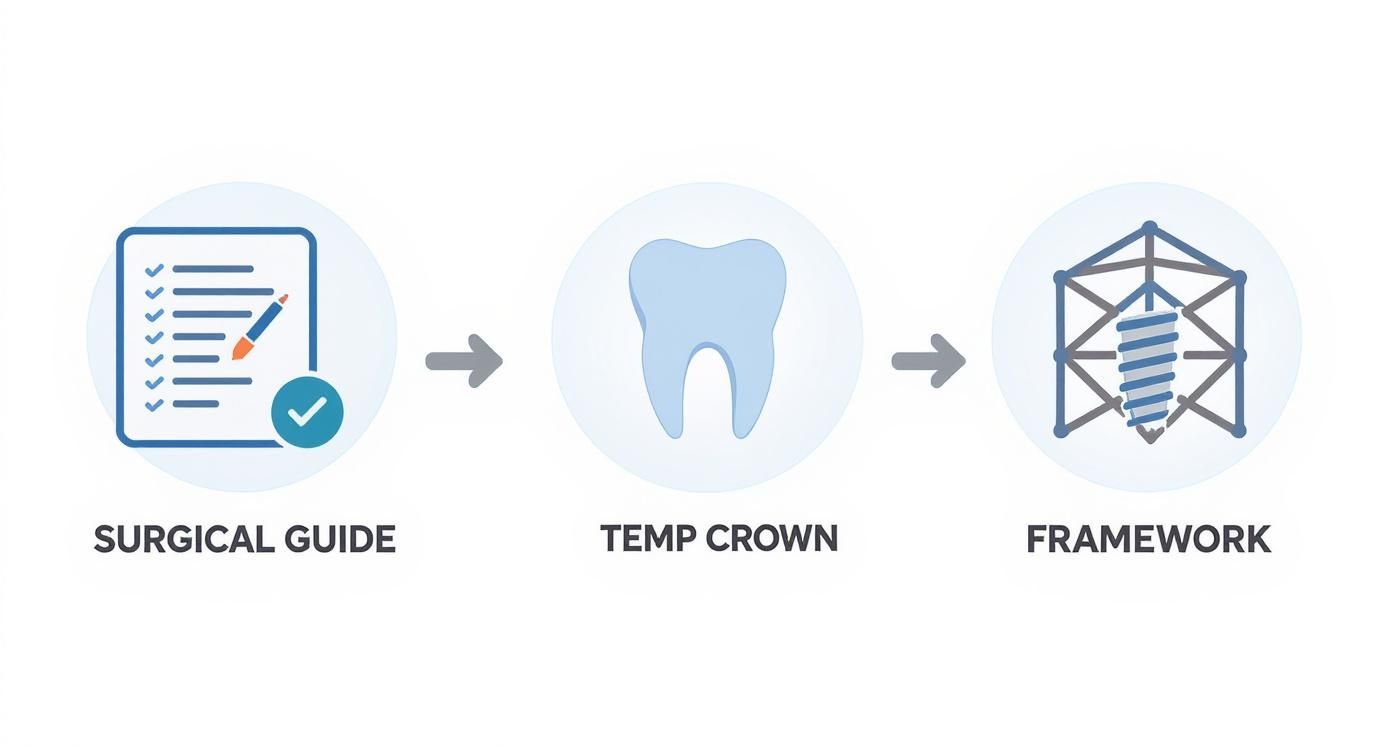

This image illustrates common components printed at this stage, from surgical guides to temporary restorations.

This visual highlights how a single digital workflow can produce multiple, highly specialized parts for one implant case.

Step 4: Finishing with Post-Processing

Parts emerging from the printer require post-processing to meet clinical standards. This crucial final stage typically involves:

- Washing: The printed object is cleaned in isopropyl alcohol (IPA) to remove residual liquid resin.

- Curing: The part is placed in a UV curing chamber to fully harden the resin, achieving final strength and biocompatibility.

- Finishing: Depending on the application, final polishing or assembly, such as inserting a metal sleeve into a surgical guide, may be required.

This comprehensive digital workflow—from scan to post-processing—creates a reliable and repeatable system, ensuring that all components are fabricated with precision, ultimately leading to superior implant outcomes.

Clinical Applications: Where Digital Plans Meet Real-World Results

The true measure of 3d drucker zahntechnik is its impact on clinical practice and patient care. A dental 3D printer transforms digital precision into tangible tools that facilitate better-fitting restorations, less invasive procedures, and predictable outcomes.

This is particularly evident in implantology, where precision is paramount. By integrating 3D printing, practices can deliver customized solutions that were once cost-prohibitive or time-consuming, turning complex cases into routine successes.

Fabricating Custom Surgical Guides

One of the most impactful applications of dental 3D printing is the creation of custom surgical guides. These devices are not mere templates but precise surgical roadmaps, designed from merged CBCT and intraoral scan data. The guide dictates the exact angulation, depth, and position for implant placement, eliminating the guesswork of freehand procedures.

For the patient, this translates to less invasive surgery, smaller incisions, reduced post-operative discomfort, and faster healing. For the clinician, it provides certainty that the implant is placed in the ideal prosthetic position, setting the foundation for a functional and aesthetic final restoration. This level of accuracy allows advanced systems, like Alfa Gate’s Bioactive implants, to achieve optimal performance.

A 3D-printed surgical guide is the physical embodiment of a perfect digital plan. It bridges the gap between virtual planning and clinical reality, ensuring that the meticulously planned implant position is executed with sub-millimeter accuracy.

Producing High-Fidelity Dental Models

While less glamorous than surgical guides, 3D-printed dental models are essential components of a digital workflow. Printed directly from intraoral scans, these models are highly accurate and stable, avoiding the distortions common with traditional plaster. They provide a perfect physical replica of the patient’s oral anatomy for various purposes.

- Diagnostic Models: Ideal for case planning and patient education.

- Orthodontic Models: Essential for planning clear aligner therapy and fabricating retainers with a precise fit.

- Crown and Bridge Models: Used by technicians to verify the fit and occlusion of restorations before final delivery.

Enabling Same-Day Provisional Restorations

Efficiency is a significant benefit for patients. With an in-house 3D printer and biocompatible resins, a clinician can design, print, and fit a provisional crown or bridge in a single appointment. This eliminates the need for multiple visits and provides the patient with a functional, aesthetic temporary that protects the prepared tooth and maintains gingival health.

This efficiency exemplifies modern, patient-focused care. Germany's dental 3D printer market, valued at USD 306.62 million in 2025 with a projected CAGR of 25.6%, underscores this trend. Practices are adopting this technology to reduce manual errors and deliver faster, more convenient treatment. You can learn more about the latest market findings from Cognitive Market Research.

These applications demonstrate that 3D printing is a core component of achieving clinical excellence. To see how these techniques integrate, explore our educational articles on digital dentistry. Ultimately, the technology delivers tangible solutions that lead to fewer appointments, better results, and higher patient satisfaction.

Integrating 3D Printing Into Your Dental Practice

Adopting a 3d drucker zahntechnik into your clinic is a strategic decision that requires careful planning. Shifting from traditional laboratory services or outsourcing digital files involves weighing the upfront investment against long-term clinical advantages and financial returns. The optimal choice depends on your practice's specific needs, production volume, and future goals.

Begin by evaluating your current workflow. Analyze your expenditures on external labs for models, surgical guides, and provisional restorations, as well as the associated turnaround times. This baseline will help you calculate the potential return on investment (ROI) of bringing these processes in-house.

In-House Printing vs. Outsourcing

A primary consideration is whether to purchase an in-house printer or partner with a digital laboratory.

An in-house printer provides complete control over production timelines and can significantly reduce the cost per unit, especially with a consistent workflow. This is an ideal solution for clinics aiming to offer same-day services and manage the entire implant process from scan to placement.

Alternatively, collaborating with a specialized digital lab offers a lower-risk entry point. You gain the benefits of 3D printing without the initial capital investment or learning curve. This hybrid approach allows your team to become proficient in sending digital files and reviewing designs, facilitating a smoother transition if you later decide to bring a printer in-house.

A Practical Checklist for Evaluating a System

When you are ready to invest, look beyond the price tag. A reliable 3d drucker zahntechnik is a long-term clinical asset.

Use this checklist to make an informed decision:

- Print Resolution and Accuracy: Does the printer consistently deliver the sub-millimeter accuracy required for well-fitting surgical guides and restorations?

- Material Compatibility: Is it an open or closed system? An open system allows you to use a broad range of certified, biocompatible dental materials for various applications.

- Software Usability: Is the accompanying software intuitive and easy for your team to learn? It should integrate seamlessly into your existing digital ecosystem.

- Technical Support and Training: Does the manufacturer provide comprehensive training and responsive technical support to minimize downtime and ensure clinical continuity?

A confident decision is all about matching the printer's capabilities to your clinical ambitions. Look for a complete, validated workflow—from the software and materials right through to the post-processing steps—that you can trust to deliver predictable and safe results for your patients.

Ultimately, integrating 3D printing is a strategic move toward a more efficient practice with greater clinical precision. For a deeper understanding of the entire process, explore the resources at our Digital Medical Academy, where we detail modern dental workflows. Choosing a partner who understands both the technology and clinical realities is key to a successful implementation.

Your Questions on Dental 3D Printing, Answered

Integrating new technology into a practice inevitably raises questions. When considering a 3d drucker zahntechnik, dentists and lab technicians want to understand its impact on their team, clinical outcomes, and patient safety. Let’s address some of the most common inquiries.

How Steep Is the Learning Curve for In-House 3D Printing?

The learning curve is more manageable than many assume. Most modern dental 3D printers are designed for clinicians, not IT specialists. With proper training, a dental assistant can typically master basic operations—such as preparing a print file and executing post-processing steps—within a few days.

Designing complex devices like surgical guides or prosthetics requires proficiency in CAD software, which can take several weeks to develop. The key to a smooth implementation is choosing a supplier who provides comprehensive training, onboarding, and ongoing support to empower your team.

How Does 3D Printing Make Surgical Guides So Accurate?

The accuracy of 3D-printed surgical guides stems from a fully digital workflow. The process begins with high-resolution CBCT and intraoral scans, which are merged to create a precise virtual replica of the patient's anatomy.

The surgical guide is designed directly on this "digital twin," defining the exact depth, angulation, and position of the implant. When printed with a rigid, biocompatible material, the guide fits securely and accurately onto the patient's dentition, eliminating the imprecision of freehand placement. This methodology minimizes human error, making implant procedures safer and more predictable—a critical factor for advanced systems like Alfa Gate’s Bioactive implants.

A 3D-printed guide acts as the physical bridge connecting your virtual plan to the clinical reality. It’s what guarantees the implant position you planned so carefully is the one you actually deliver, with sub-millimetre precision.

What Biocompatibility Standards Do I Need to Know?

Patient safety is non-negotiable. Any 3D-printed device intended for intraoral use must be fabricated from biocompatible materials that are certified under the appropriate regulatory frameworks, such as the CE mark for Europe's Medical Device Regulation (MDR). Materials are classified based on the duration of patient contact.

For example, surgical guides have brief contact and are typically classified as Class I medical devices. Materials for temporary or permanent restorations, however, must meet the more stringent Class IIa standards to ensure they are safe for long-term intraoral use. It is essential to use a fully validated workflow—where the printer, material, and post-processing protocols are tested together—to ensure the final part is both safe and clinically effective. You can find more information on validated digital protocols in our educational resources.

Are you ready to elevate your practice with a predictable, high-quality implant system that seamlessly integrates with your digital workflow? At Alfa Gate, we deliver advanced solutions designed for the demands of modern dentistry. Explore our innovative implant systems or Contact Us to discover how we can support your clinical success.