A Guide to 3D Druck Zahntechnik in Modern Dentistry

The term 3D Druck Zahntechnik describes the application of additive manufacturing to produce highly customized dental models, surgical guides, and restorations directly from digital designs. This technology represents a significant departure from traditional analog methods, offering superior accuracy, accelerated production times, and an efficiency that conventional fabrication cannot match. It is fundamentally reshaping the landscape of the modern dental laboratory and clinical practice.

The Digital Shift in Modern Dental Technology

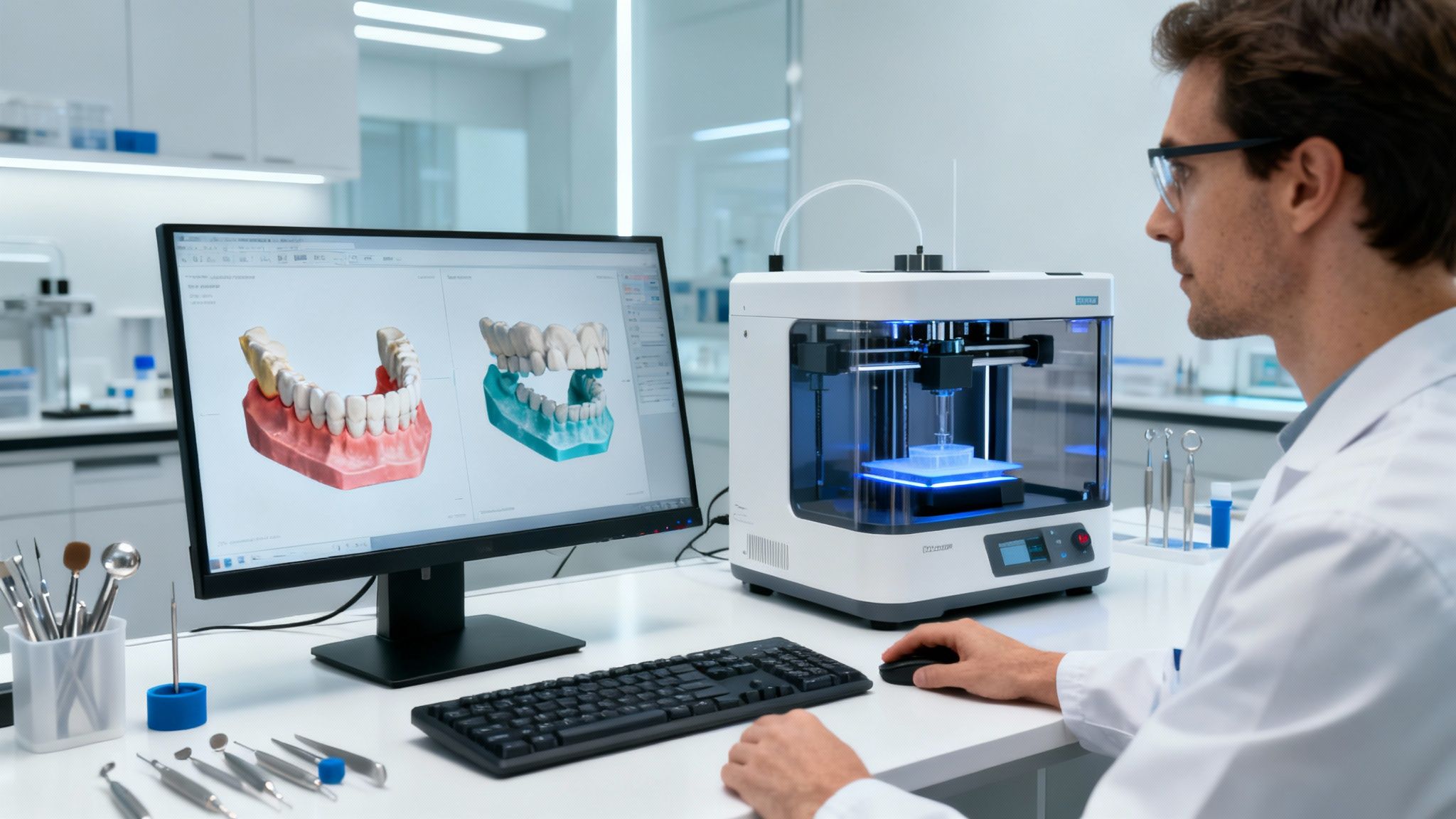

Dental laboratories are undergoing a profound transformation, replacing handcrafted analog techniques with the precision of digital fabrication. The integration of 3D printing is not an incremental improvement but a foundational leap. This technology empowers dental professionals to manage the entire clinical workflow, from initial intraoral scanning to the final placement of a restoration, with enhanced control and predictability.

This digital workflow enables the production of a diverse range of dental applications with remarkable speed and consistency. For both clinics and laboratories, this translates directly into improved productivity and a higher standard of patient care, establishing digital dentistry as the new benchmark for excellence.

Key Advantages Of Digital Fabrication

Transitioning to a fully digital workflow provides distinct clinical and operational advantages over traditional methodologies:

- Pinpoint Precision and Accuracy: Digital designs are translated into physical objects with micron-level accuracy. This precision minimizes the need for manual adjustments and ensures a superior fit for restorations and appliances, which is critical in complex implant cases.

- Boosted Efficiency and Speed: Additive manufacturing systems can operate continuously, significantly reducing turnaround times. A surgical guide that once required days to fabricate can now be printed and prepared for clinical use in a matter of hours.

- Unwavering Consistency: Digital files ensure that every printed component is an exact replica. This eliminates the inherent variability of manual fabrication, leading to predictable and reliable outcomes for every patient.

- Smarter Economics: By minimizing material waste and reducing manual labor requirements, 3D printing offers significant long-term cost efficiencies for dental practices and laboratories.

The adoption of digital fabrication is a strategic shift toward data-driven, patient-centric care. To fully leverage the benefits of 3D-printed surgical guides, integration with advanced imaging like cone-beam computed tomography is essential. You can learn more in our overview of digital workflows in dentistry.

Market projections underscore the industry's confidence in this technology. In Germany, the dental 3D printing market was valued at USD 235.5 million in 2023 and is forecasted to reach USD 1,171.6 million by 2030. You can discover more insights about these market trends on grandviewresearch.com. This rapid growth reflects the widespread adoption of digital workflows.

Understanding Core 3D Printing Technologies

Navigating the world of 3d druck zahntechnik requires an understanding of the primary technologies available. While the market offers a wide array of printers, most fall into one of three main categories: Stereolithography (SLA), Digital Light Processing (DLP), and Selective Laser Sintering (SLS).

Each technology builds objects layer by layer from a digital file, but their mechanisms differ significantly. Understanding these differences is the first step in selecting a system that aligns with the specific clinical and production needs of a practice or laboratory.

Stereolithography (SLA): The Master of Detail

Stereolithography (SLA) operates by using a high-precision ultraviolet (UV) laser to selectively cure liquid photopolymer resin. The laser meticulously traces each layer of the object onto the resin surface, solidifying it point by point.

This methodical process is why SLA is renowned for its exceptional precision and ability to produce parts with a smooth surface finish and intricate detail. For applications where accuracy is paramount, such as diagnostic models or temporary crowns, SLA is often the preferred technology.

Digital Light Processing (DLP): Built for Speed

Digital Light Processing (DLP) functions similarly to a digital projector. Instead of a single laser point, a DLP system projects an entire layer's image onto the resin vat at once, curing the whole cross-section simultaneously.

This fundamental difference in curing makes DLP significantly faster than SLA. It can produce multiple surgical guides, orthodontic models, or custom impression trays in a fraction of the time. For high-throughput environments where productivity is a key consideration, DLP provides an optimal balance of speed and quality.

Selective Laser Sintering (SLS): The Powerhouse for Strength

Selective Laser Sintering (SLS) is a powder-bed fusion technology. It utilizes a powerful laser to selectively fuse particles of a polymer or metal powder, layer by layer. The machine spreads a thin layer of powder, and the laser sinters the material to form a solid cross-section.

SLS is unmatched for creating strong, durable, and functional parts. In dentistry, it is primarily used to fabricate robust metal frameworks for removable partial dentures, crowns, and bridges from materials like cobalt-chrome. A key advantage is its self-supporting nature, which eliminates the need for support structures and allows for greater design freedom.

The selection of a 3D printing technology should be driven by its primary clinical application. As detailed in our guide to CAD/CAM dental technology, aligning the technology with the clinical task is fundamental to success. A prosthodontist focused on aesthetic models may prefer SLA, whereas a laboratory manufacturing metal frameworks would find an SLS system indispensable.

The following table provides a concise comparison of these key technologies.

Comparison of Key Dental 3D Printing Technologies

This table provides a side-by-side comparison of the most common 3D printing technologies used in dentistry, highlighting their primary mechanism, best use cases, key advantages, and typical materials.

| Technology | Mechanism | Primary Dental Applications | Key Advantages |

|---|---|---|---|

| SLA | A UV laser cures liquid resin point-by-point. | High-detail models, temporary crowns, casting patterns. | Exceptional accuracy and smooth surface finish. |

| DLP | A digital projector cures an entire resin layer at once. | Surgical guides, orthodontic models, custom trays. | High speed and good throughput for volume production. |

| SLS | A laser sinters powdered material layer-by-layer. | Metal frameworks for RPDs, crowns, and bridges. | High strength, durability, and no need for support structures. |

Choosing the right printer is a strategic decision that impacts production timelines, cost-effectiveness, and final clinical outcomes. Whether you are a distributor advising clients or a clinician investing in your practice, understanding these foundational differences is crucial.

Our team can help you determine which system best fits your clinical or business needs. Contact us to discuss your specific requirements and learn how Alfa Gate’s digital solutions can support your goals.

Selecting the Right Materials for Clinical Success

An advanced 3D printer is only as effective as the materials used within it. In the context of 3d druck zahntechnik, material selection is a critical clinical decision that directly influences patient safety, prosthetic fit, and aesthetic results.

The true utility of modern 3D printing lies in the wide variety of specialized materials available, each engineered for a specific clinical purpose. From biocompatible resins for surgical guides to robust polymers for dental models, understanding the properties of each material is key to producing reliable and effective dental appliances.

Biocompatible Resins for Patient-Contact Applications

For any component intended for intraoral use—including surgical guides, splints, custom impression trays, and temporary restorations—biocompatibility is the primary consideration. These materials must be certified as safe for patient contact to prevent irritation or adverse biological reactions.

Consequently, these resins are classified as medical devices and must adhere to stringent regulatory standards. Key properties include:

- Low cytotoxicity: The material must not be harmful to living cells.

- High flexural strength: It must be durable enough to withstand occlusal forces, particularly for temporary restorations.

- Dimensional stability: The printed part must maintain its precise form after printing and post-curing to ensure an accurate fit.

- Aesthetic qualities: For provisional restorations, materials should offer tooth-like shades and translucency for a natural appearance.

High-Performance Polymers for Models and Lab Work

For applications confined to the dental laboratory—such as diagnostic models, aligner molds, and working dies—the focus shifts to accuracy, durability, and cost-effectiveness to optimize the laboratory workflow.

Model resins are engineered for exceptional precision, faithfully replicating every detail from an intraoral scan with minimal distortion. They must also be rigid and abrasion-resistant, allowing technicians to work on them confidently. This precision forms the basis for creating final restorations that fit flawlessly.

Selecting the appropriate material is analogous to a surgeon choosing the correct instrument. A material optimized for a rigid, accurate surgical guide would be unsuitable for a flexible gingival mask. The success of the final clinical outcome is determined well before the printing process begins.

Navigating Regulatory and Quality Standards

Materials used in dental 3D printing are strictly regulated to ensure patient safety. In Europe, the CE marking indicates that a product meets the required health, safety, and environmental protection standards for the European Economic Area.

For medical-grade materials, compliance with ISO 10993—the global standard for the biological evaluation of medical devices—is essential. This certification provides assurance that the material has undergone thorough testing for potential biological risks. It is imperative to partner with suppliers who provide clear documentation and certification for their products.

This focus on quality and safety is driving advancements in material science. The German dental 3D printing materials market, for instance, is projected for steady growth, built upon a foundation of robust engineering and regulatory frameworks. Explore detailed forecasts on the German dental materials market here.

Ultimately, proper material selection enables dental professionals to realize the full potential of 3d druck zahntechnik. It transforms the printer into a powerful clinical tool capable of producing a wide range of patient-specific solutions, from precise Alfa Gate implant surgical guides to aesthetic temporary restorations.

Mastering the Digital Dental Workflow

The true power of 3D printing in dental technology lies in the integrated digital workflow it enables. This seamless process, from data acquisition to the final physical appliance, involves several key stages. Mastering this workflow is essential for unlocking the full potential of additive manufacturing in a clinical or laboratory setting.

The entire process is designed to convert digital information into a physical solution with exceptional precision. Each step is foundational to the next, culminating in a final product that is both accurate and safe for clinical use.

Step 1: Intraoral Scanning and Data Acquisition

The workflow begins with data acquisition, typically using an intraoral scanner to capture a detailed digital impression of the patient's dentition and soft tissues. This method is faster and more comfortable for the patient than traditional impressions and avoids the potential for material-based distortions.

The output is a precise 3D model, commonly in an STL file format. This digital blueprint contains all the critical anatomical information required for the subsequent design phase.

Step 2: Computer-Aided Design (CAD)

The digital scan is imported into specialized CAD software. Here, the dental professional designs the required appliance, whether it is a surgical guide, a temporary crown, or a model for clear aligners. This stage provides complete control over fit, occlusion, and aesthetics.

For implantology, this step is crucial for designing a surgical guide that ensures the precise placement of implants like the Alfa Gate M+ Conical Connection Implant, aligning with the planned prosthesis for an optimal functional and aesthetic outcome.

Step 3: Computer-Aided Manufacturing (CAM) and Print Preparation

Once the design is finalized, the file is transferred to CAM software for print preparation. This process, often called "slicing," divides the 3D model into hundreds or thousands of thin horizontal layers that the printer will build sequentially.

In this stage, the part is oriented on the build platform to optimize print quality and efficiency. Support structures are also added where necessary to prevent warping and ensure the stability of complex geometries during the printing process.

Step 4: Post-Processing for Clinical Use

Printing is only one part of the manufacturing process. Post-processing is a critical final step that ensures the component achieves its intended strength, accuracy, and biocompatibility. For any patient-contact application, these procedures are mandatory.

The standard post-processing workflow includes:

- Washing: The printed part is cleaned in a solvent, typically isopropyl alcohol (IPA), to remove any uncured liquid resin from its surface.

- Curing: After washing and drying, the part is placed in a UV curing chamber. This final curing process fully polymerizes the resin, ensuring maximum strength and stability.

- Support Removal and Finishing: The support structures are carefully removed, and the part is finished as needed (e.g., polishing) to achieve a smooth surface. It is now ready for clinical use.

The digital workflow is an interconnected chain; its strength is determined by its weakest link. A perfect scan can be compromised by improper post-processing, just as an excellent print cannot correct a flawed initial design. Consistency across all stages is paramount.

This infographic summarizes the core principles guiding material selection and processing to achieve successful clinical results.

A successful outcome depends on a balance of strength, aesthetics, and safety—all of which are finalized during post-processing. By adhering to this structured workflow, dental professionals can consistently produce high-quality, patient-specific solutions.

Clinical Applications of 3D Printing

Understanding the technology is important, but its true value is demonstrated through its impact on patient care. 3D druck zahntechnik is not a futuristic concept; it is a practical tool that is elevating the standard of care in daily practice.

From implantology to prosthodontics, 3D printing provides solutions to real-world clinical challenges. The ability to transition seamlessly from a digital design to a physical object allows clinicians to execute treatment plans with a level of precision previously unattainable.

Precision Implantology with Surgical Guides

The fabrication of surgical guides is one of the most impactful applications of dental 3D printing. These custom templates are designed using CBCT scans and digital impressions, ensuring a precise fit to the patient's anatomy.

A 3D-printed guide dictates the exact angle, depth, and position for implant placement. This removes the uncertainty of freehand surgery, leading to more predictable osseointegration, improved prosthetic outcomes, and reduced surgical time. In complex cases with anatomical limitations, this level of accuracy is a critical safety feature. You can learn more about this in our guide on creating dentures with digital tools.

Enhanced Case Planning with Detailed Models

Complex restorative and orthodontic cases require meticulous planning. 3D-printed dental models, created from intraoral scans, provide highly accurate physical replicas of a patient's oral anatomy. These models are invaluable for:

- Diagnostic wax-ups: Enabling visualization of the final restorative outcome before treatment begins.

- Patient communication: Facilitating clear communication of the proposed treatment plan.

- Appliance fabrication: Serving as a precise base for creating appliances like clear aligners.

Unlike traditional stone models, these are durable, consistent, and can be reprinted at any time from the original digital file, ensuring a high level of quality control.

The ability to hold a precise physical model of a complex case allows for better risk assessment, improved collaboration between the clinician and the laboratory, and a more confident approach to treatment.

The Rise of Chairside 3D Printing

The trend toward chairside 3D printing represents a significant evolution in clinical practice. It brings the capabilities of a dental laboratory directly into the clinic, enabling same-day dentistry for a variety of applications.

Clinicians can now print temporary crowns, bridges, and custom impression trays on-site. This drastically reduces turnaround times, minimizes the number of patient appointments, and enhances the overall patient experience. Market data confirms this trend, with the in-office chairside 3D printing market in Germany projected to grow from USD 78.48 million in 2025 to USD 464.18 million by 2035.

The versatility of 3D druck zahntechnik makes it an indispensable tool across all dental specialties, delivering practical solutions that streamline workflows, enhance clinical precision, and ultimately improve patient care.

Ensuring Precision with Quality Control Protocols

In 3d druck zahntechnik, manufacturing a restoration or appliance is only part of the process. The critical subsequent step is ensuring that the printed object is a perfect physical replica of its digital design. In dentistry, precision is the foundation of clinical success, patient safety, and professional integrity.

Implementing robust quality control (QC) protocols is therefore essential. A systematic QC process guarantees that every component, from a surgical guide to a temporary crown, is accurate, consistent, and safe for clinical use. It is a demonstrable commitment to excellence that validates the reliability of your digital workflow.

Calibrating for Consistent Accuracy

A 3D printer is a precision instrument that requires regular calibration to maintain its accuracy. Environmental factors such as temperature, humidity, and minor vibrations can affect print outcomes over time. Consistent calibration is the primary defense against these potential inaccuracies.

Most professional dental printers include straightforward calibration routines. This typically involves printing a standardized test part and measuring its dimensions against the source file. This simple yet critical procedure ensures the printer’s mechanical and optical systems remain perfectly aligned, guaranteeing that prints are true to the CAD design.

Validating Printed Parts Against CAD Designs

After printing and post-processing, every part must be validated. The goal is to confirm that the physical object is an exact match to its digital blueprint. While a visual inspection is a good first step, objective verification is necessary for true quality control.

- Digital Comparison: Advanced practices often use a 3D scanner to create a digital model of the final printed part. This scan is then superimposed onto the original CAD file using specialized software, which generates a color-coded map highlighting any microscopic deviations. This provides quantitative data on the part's dimensional accuracy.

- Physical Fit Checks: For components like crowns or implant guides, a physical fit test is indispensable. Placing the part on a 3D-printed model of the patient’s arch is a practical method for validating the fit, seating, margins, and contact points before the patient’s appointment.

Quality control bridges the gap between digital design and clinical reality. Without rigorous validation, even the most advanced 3d druck zahntechnik workflow produces unverified objects rather than reliable medical devices.

Upholding Biocompatibility Standards

For any component intended for patient contact, quality control must extend beyond dimensional accuracy to include biological safety. The use of medically certified printers and materials is non-negotiable for meeting regulatory standards and ensuring patient health.

The key standard is ISO 10993, which outlines the biological evaluation of medical devices. Materials with this certification have undergone extensive testing to confirm they are not cytotoxic and will not cause an allergic reaction. A critical part of any QC protocol is the meticulous documentation of material batch numbers for each patient-specific device. This establishes full traceability from the manufacturer to the clinic and reinforces patient trust.

Frequently Asked Questions About Dental 3D Printing

Adopting a new digital workflow naturally raises practical questions. Understanding the implementation of 3D Druck Zahntechnik is key to making an informed decision for your practice or laboratory. Here, we address some of the most common inquiries from dental professionals.

The initial investment for a dental 3D printer varies depending on the technology (SLA, DLP, or SLS) and the required production volume. An entry-level desktop printer suitable for models and surgical guides can be acquired for several thousand euros. Conversely, high-throughput systems designed for large-scale laboratory production represent a more significant capital investment.

It is important to consider the total cost of ownership, which includes design software, a consistent supply of specialized materials, and necessary post-processing equipment, such as wash and cure stations.

How Steep Is The Learning Curve For My Team?

While any new technology requires an adjustment period, modern dental 3D printers are designed with user-friendly interfaces. The most skill-intensive aspect is typically the Computer-Aided Design (CAD) phase, which demands both technical proficiency and clinical knowledge.

Teams already familiar with digital dentistry and other CAD/CAM systems will experience a shorter learning curve. Reputable manufacturers provide comprehensive training and ongoing support to ensure your team becomes proficient and productive within a few weeks.

Can 3D Printing Integrate With My Existing Digital Equipment?

Yes. The majority of professional dental 3D printers are based on an open-system architecture. They are designed to be compatible with STL files, the universal format used by nearly every intraoral scanner and dental design software on the market.

This interoperability is a significant advantage. It allows you to integrate a new 3D printer into your existing digital workflow without replacing the scanners and design software in which you have already invested.

This flexibility enables a seamless and logical upgrade of your technological capabilities without disrupting established clinical processes, making 3D Druck Zahntechnik an efficient enhancement to modern dental practice.

At Alfa Gate, our mission is to empower dental professionals with advanced digital solutions. From our world-class implant systems to comprehensive educational resources, we provide the tools necessary for clinical excellence. We encourage you to explore our innovative implant options or inquire about how to become a distributor and partner with a global leader in dental technology.